Vitrified bond grinding wheels are a type of abrasive wheel that utilizes a vitrified (glass-like) bond to hold the abrasive grains together. This bond is created through a process of heating clay, feldspar, and other materials to high temperatures, which results in a hard, durable, and porous structure.

Vitrified Bond Grinding Wheels

- 1.Material Composition: The bond is primarily made from natural and synthetic materials, including clay and other additives that, when fired at high temperatures, create a strong bond

- 2.Porosity: Vitrified wheels have a porous structure that allows for effective cooling and chip removal during the grinding process. This helps prevent overheating and preserves the integrity of the workpiece

- 3.Precision: Vitrified bond wheels are known for their ability to produce fine finishes and hold tight tolerances, making them suitable for precision grinding applications

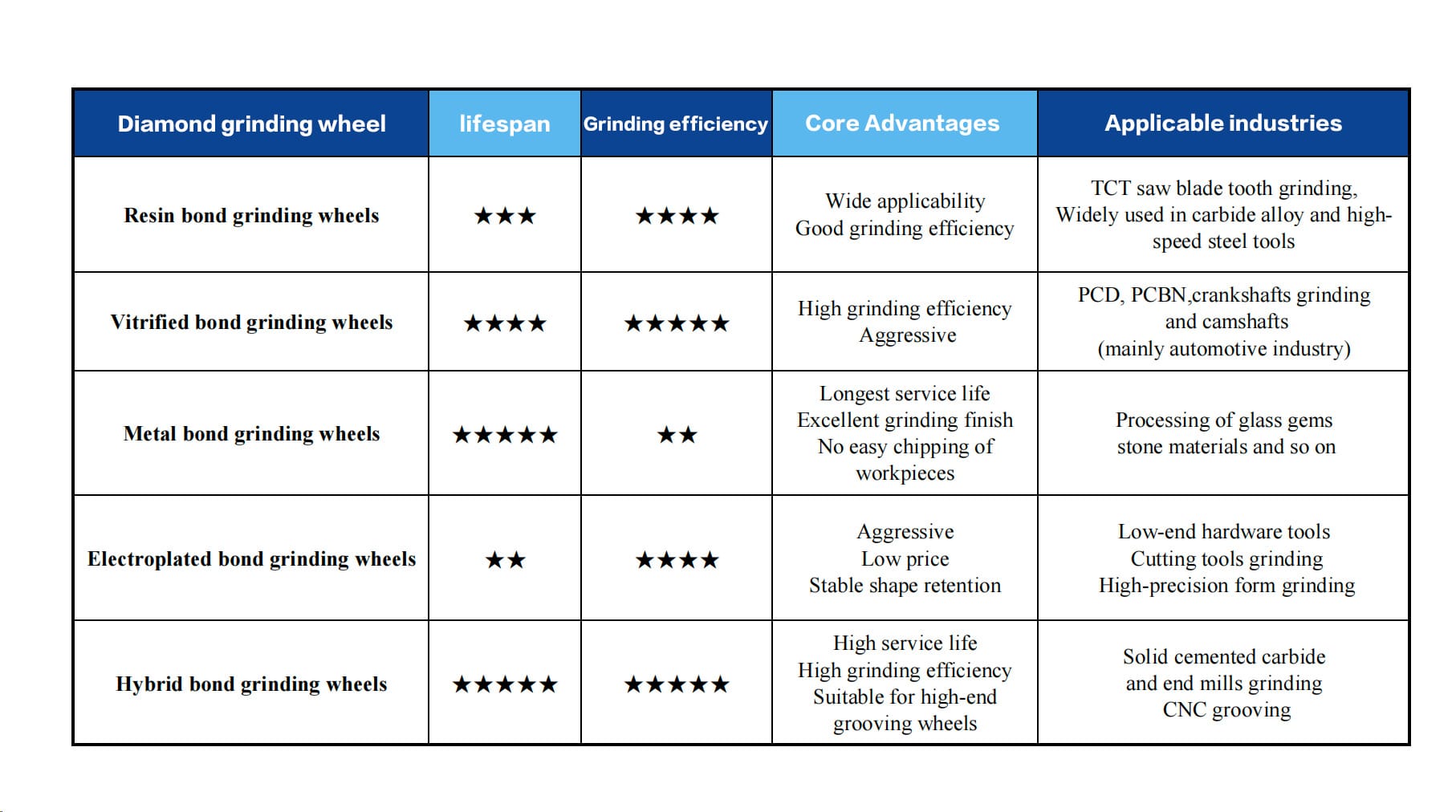

Category

Diamond Grinding Wheels classified by their bonding materials, which influence their performance, application, and durability.

Vitrified Bond Grinding Wheels

| Diamater (mm) | Thickness (mm) | Hole Diameter (mm) | Diamond Thickness (mm) | Width (mm) | Common Grit |

| 20-900 | 1-100 | customized | 1-50 | 1-50 | D81 D126 D151 D181 D91 D64 D46 |

| Diamater (Inch”) | Thickness (Inch”) | Hole Diameter (Inch”) | Diamond Thickness (Inch”) | Width (Inch”) | Common Grit |

| 1″-36″ | 0.04”-3.94” | customized | 0.04”-1.97” | 0.04”-1.97” | D81 D126 D151 D181 D91 D64 D46 |

1. The finest diamond grit can reach 10000

2. These wheels can be manufactured in various shapes, sizes, and grit types, making them versatile for different grinding tasks

Applications

Applications-

Metalworking Industry

-

Stone and Concrete Processing

-

Glass Manufacturing

-

Woodworking Industry

-

Aerospace and Automotive Industries

-

Oil and Gas Exploration

What can you get?

Applications-

Customized Solutions

We provide customized solutions for product development, process optimization, and system integration, collaborating closely with you to deliver the best strategies for your needs.

-

Professional Consulting Services

Our experienced team offers professional consulting services to keep your business competitive, providing in-depth analyses and actionable strategic advice.

-

Comprehensive Technical Support

We offer comprehensive technical support for smooth system operations, including troubleshooting, maintenance, and user training, ensuring timely and professional assistance.